- Case Studies

- Choosing a Software

- Implementation

- Manufacturing Tips

- Production planning

- Supply Chain

What Is the Difference Between Production Planning and Scheduling?

Production planning and production scheduling are similar and interconnected concepts, but there are also differences that professional manufacturers understand.

You can also listen to this article:

Table of Contents

Production planning and scheduling are similar concepts. However, there are notable differences between them.

The resources needed for production planning and scheduling are:

- Machinery, equipment.

The first four elements on the list are material assets.

The management, however, is the brain that defines how to convert the raw materials into final products. It is the “software” of the company, or in other words, the way of performing business activities. For example, two companies producing similar articles can have completely different ways and processes for doing so.

It is the management’s task to combine the first four elements in the most efficient way to make finished goods.

Easily plan and schedule production with MRPeasy

Production Planning

Production planning involves the whole manufacturing process on a high level in order to plan the production of finished goods. With planning, it is possible to map out the whole process, from gathering the resources to producing the final products.

Production planning balances the resources and the demand.

- Quantities to produce from a product family

- Desired inventory levels

- Resources to use per period

- Investments necessary to match capacity and demand

The time horizon for production planning is from 6 months to 3 years and involves the top management. The planning buckets, the smallest distinguished units of time, are weeks or months.

Read more about Production Planning .

Components of Production Planning

The required inputs for making a proper production plan are:

- Bill of Materials : the broken-down list of components and subcomponents that make the final product.

- The availability of items in stock: sometimes it is necessary to purchase more; sometimes they are already on hand.

- Cost of resources, to produce items in compliance with quality needs.

- Lot sizes involving the frequency and the proper volume to have the right quantity on hand. It prevents the organization from falling into stock-outs or excesses of stock.

- The manufacturing lead time , which means the time that production takes to convert the raw material into finished goods.

To give a simple example from daily life, assume you are making a cake. You will need to know:

- The ingredients you combine to make a cake (the bill of materials or BOM)

- The ingredients you already have at home (stock on hand)

- The ingredients you need to buy (purchasing)

- How much the preparation will cost (the cost of resources)

- How much of the ingredients and when you need them (the frequency and lot sizes)

- How long it will take to produce a cake that would be enough for all the guests (the lead time)

The next step involves the internal combination of resources to produce the final items. In the case of the cake example, it would mean cooking it.

Production Scheduling

Production scheduling is more detail-oriented in comparison to production planning. It is also the next step going from general to detail. The time horizon is shorter than in production planning and has a higher level of detail:

- It defines the production quantities of single finished products or SKUs, instead of product families.

- It defines who or which machine will produce every single SKU.

- The time horizon is shorter and more detailed, between one month and one year, depending on the industry and management type.

- The planning buckets could be as short as hours or minutes.

- It defines the inventory level of single finished products or SKUs, instead of product families.

- It requires a higher review frequency of middle management and involves the shop floor more.

After production planning, the next step is to create a detailed production schedule.

The goal is to schedule every single operation at a certain time in the calendar, assign the resources and workers, and plan all the detailed steps.

It is not a forecast, but it needs to see the future and to get the appropriate resources where they need to be when they need to be. It is a bridge between production planning and actual production and it helps to allocate the necessary resources in a timely manner.

Read more about Production Scheduling .

Components of Production Scheduling

Production scheduling involves:

- Identifying and assigning the appropriate number of workers

- Identifying and allocating the appropriate raw materials

- Identifying and assigning appropriate machinery and equipment

- Synchronizing all the resources to define priorities and fulfill customer needs.

As you can see, in both stages it is important to understand that resources are finite. The purpose is to combine the limited resources to make the final products in the most effective way. Production planning establishes when something could be made in general while scheduling looks at how and when something will be made in much more detail.

Production Planning and Scheduling example

Let’s say your organization sells a variety of chips to the market. The operational team will start preparing the production plan and, at this stage, they will define:

- The volume of chips they expect to sell within one year.

- The capacity of ovens, fryers, bag makers, etc. necessary to sustain the sales volume every month.

- The infrastructure (layout, space, equipment, pallets, forklifts, tools) necessary to operate without bottlenecks.

- The number of workers and skills necessary to operate the machinery.

- The number of shifts available and needed during the year.

- The desired inventory levels of flour, oil, salt, additives, water, potatoes, corn, packaging, and other raw material at the beginning and end of every month.

- The expected amount of tons and units necessary in the finished good warehouse at the beginning and end of every month to respond to demand.

Following the chips company example, the company will proceed to the next stage: production scheduling. At this stage, the following questions will be answered:

- Which machine will be running each shift, day, and week?

- Who is going to operate each machine each shift, day, and week?

- What is the necessary amount of ingredients, when they must arrive, and when they must be ordered?

It is important to remark that both production planning and production scheduling are irreplaceable parts of a well-organized manufacturing business. Production planning is the natural first step and production scheduling comes in as the more detailed extension of that.

Thanks to these processes, it is possible to achieve accurate production schedules and efficient production control. Finally, production activity will provide the actual volumes and results, and the statistics can be used to further improve both processes.

You may also like: Forward Scheduling vs. Backward Scheduling in Production Planning

Get manufacturing know-how delivered to your inbox!

Karl H Lauri

For more than 5 years, Karl has been working at MRPeasy with the main goal of getting useful information out to small manufacturers and distributors. He enjoys working with other industry specialists to add real-life insights into his articles, with a special focus on using the feedback from manufacturers implementing MRP software. Karl has also collaborated with respected publications in the manufacturing field, including IndustryWeek and FoodLogistics.

Related articles

Privacy Policy Update

You can read our full privacy policy and terms of service .

These cookies help us track site metrics to improve our sites and provide a better user experience.

These cookies used to serve advertisements aligned with your interests.

These cookies are required to provide basic functions like page navigation and access to secure areas of the website.

Don't Leave Yet!

What is production planning and how to do it? A comprehensive guide.

Production planning is crucial for efficient production. Let’s explore all about it and see how to handle it in ERP software.

Production planning is vital to fulfil orders on time. If you don’t know your stock levels, workstation availability, or job schedules, you won’t be keeping your customers happy.

Whether you’re a new manufacturer oiling your machinery for the first time or a seasoned manufacturer shipping thousands of items, production planning is a must. Similar to how scrums and monthly plans run operations smoothly, production plans ensure optimal usage of resources.

In this blog, let’s understand the basic terms around production planning, see how it’s done, look at common pitfalls to be aware of, see the types of production planning, some topics around production planning, and finally an example of handling production planning in ERPs.

1. Production planning basics

1.1 what is production planning.

Production planning is the planning and allocation of raw materials, workers, and workstations to fulfill manufacturing orders on time. In a make to order environment, manufacturing orders or work orders themselves are created after receiving customer orders. A company that follows make to stock style of manufacturing will create work orders on a timely basis depending on demands. Production plans are usually set by the production managers who supervise the shop floor. A good production plan makes the best use of available resources to deliver orders on time.

1.2 Why should you do production planning

Handling a few production orders in spreadsheets works but for large manufacturing shops, the complexity increases a lot. Production planning helps to plan the procurement of raw materials based on the quantity of finished products to be manufactured. It also affects inventory, cash flow, sales, and distribution.

2. How to do production planning

2.1 five tips to improve production planning.

These tips to keep your production plan on track and improve its efficiency

2.1.1 Forecasting demand

Before production planning, the first action to take is forecasting demands for your products. While this may not be accurate to the last digit, getting rough estimates rolling is important to allocate resources. Forecasting can be done based on factors like historical order data and market trends/demands. Drawing out proper forecasts helps planning the type and quantity of materials to be produced and also the planning of raw material procurement.

2.1.2 Control inventory

Both, inventory shortage and inventory surplus are undesirable states. You can’t proceed with production when there’s a shortage and you waste space and money when there’s a surplus. Efficiently controlling inventory involves reordering when current inventory dips below a certain level, calculating the lead times to order items with long lead times earlier, and factoring in storage conditions. A well-controlled raw material inventory helps run a smooth production line and outputs finished goods inventory on time.

2.1.3 Plan for everything and everyone

Often, when making production plans, some machine or some person is unaccounted for. The problem here is that that machine may go down or the worker may be on leave, or worse, working on something else. Hence, plan for every machine, raw material, workstation, warehouse, and employee.

2.1.4 Monitor

Once the production plan is final and work orders are handed out, the manufacturing process begins. At this point, things may go wrong, machines pause, or items may get misplaced. Constantly monitoring the factory floor with supervisors or with IoT devices ensures that all the pieces are moving as planned.

2.1.5 Adapt

Despite your best planning, things go wrong on the factory floor. Anything can happen from suppliers making late deliveries to workers falling sick to machines failing. It’s important to be flexible and adapt to these changes quickly so that the planned quantities can be delivered on time. Ideally, you should also plan for any such risks beforehand.

2.2 KPIs for production planning

A few key performance indicators to track in production planning are:

- Production cost : This is essentially the monetary cost involved in producing the item. Costs include raw materials, electricity, fuel, worker salaries, rent, etc.

- Capacity utilization rate : It’s the percentage of actual manufacturing output against the total possible manufacturing output. If many machines and workers are sitting idle, your capacity utilization is low. Ideally, you want it high but never full.

- Projected versus actual hours : When planning, you may allocate a certain number of hours for completion of the production plan. But, it may take longer due to delays from workers or unexpected tasks. This KPI gives you a picture of how much time it was supposed to take and how much it did.

- Employee utilization (productivity) : You want workers to be working properly during the punch in and punch out. Nobody wants to be a machine by working to the dot but working 4 hours out of 8 is also not reasonable.

- Takt time : Takt time is a lean manufacturing concept. It is the time taken to produce a single unit of item.

3. Production planning pitfalls and avoiding them

First, let us understand the pitfalls or things that could go wrong during production planning. These occur in areas from idle inventory storage to active workers.

3.1 Stockouts

What is it?

It’s the shortage of raw materials that can happen after fulfilling large orders or due to negligence.

How to avoid it?

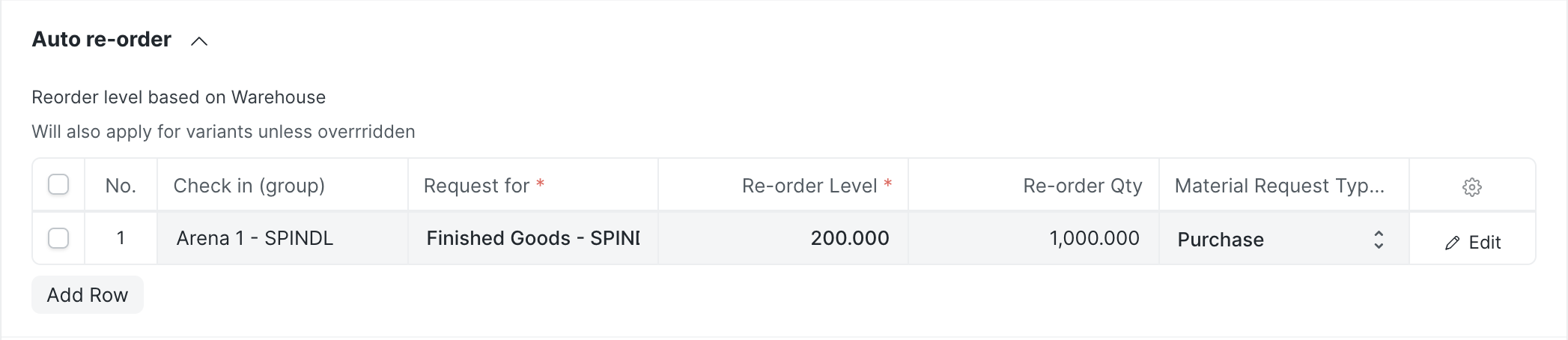

By checking inventory reports regularly or better yet, setting up automatic reordering.

How to do it?

By setting automatic reordering like this:

3.2 Assigning work to workstation on downtime

Assigning operations to a workstation that was supposed to be on downtime. This causes confusion and the work doesn’t get done because there’s no machine available.

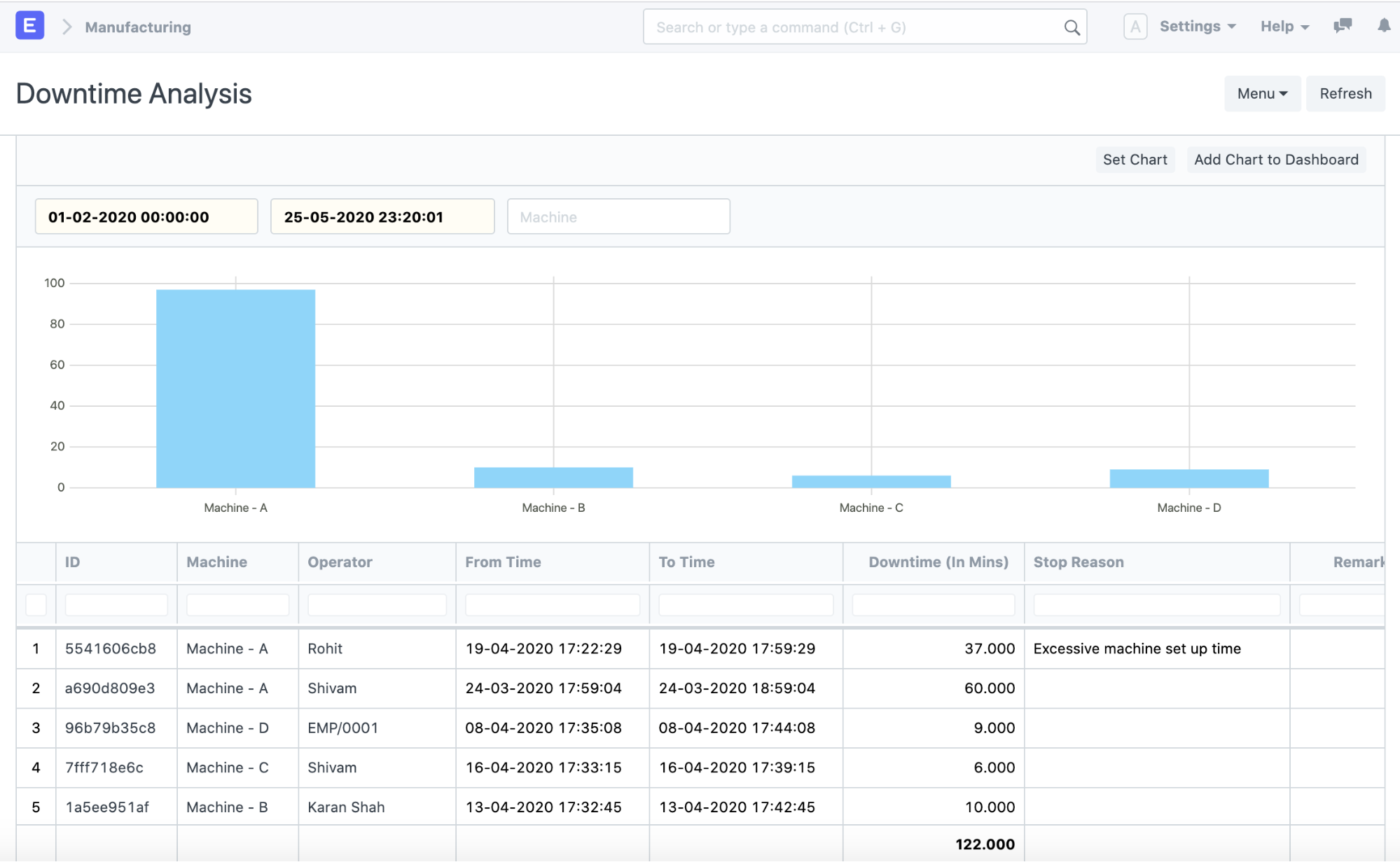

Get a view of which workstations are on downtime and assign only to available machines. (version 13)

By analyzing the downtime of different machines and assigning work appropriately:

3.3 Bottlenecks

These are roadblocks in the production line that halt the processing of materials midway. For example, if items are waiting at the painting stations to get painted, the painting station is a bottleneck since it’s stopping the items from going ahead.

Bottlenecks can happen anywhere in the production line. Scan all the machines and even check if there are enough workers to carry out tasks. Through planning and ensuring the availability of machines and resources is a good way to avoid bottlenecks.

Setting up regular maintenance activities helps by keeping machines running. Eliminating bottlenecks in the production depends a lot on having sufficient machinery, manpower, and a regular supply of raw materials.

3.4 Insufficient worker training

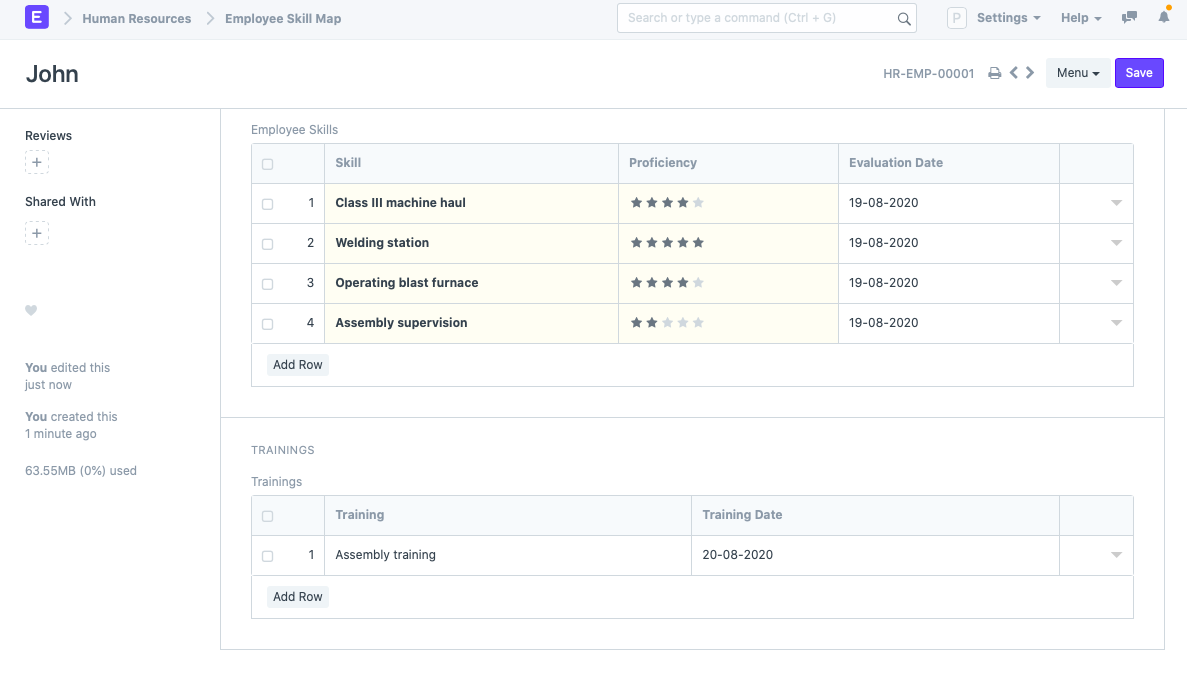

Some specialized machines need trained workers for operation. Hiring rookies running specialized machines result in work not getting done.

Interview candidates for skills and experience in operating similar machinery. Even after interviews, thorough training should be done to ensure that the worker is ready to use the machines in production.

From the human resources module, first, test the employee’s skill proficiency. Then, set training events to enhance their skills. Updated employee skill maps help supervisors better allocate work to the right people and help the ones that are lagging.

4. Types of production planning

The different types of production planning are based on the manufacturing process followed in the factory. A single organization can deal with different types of manufacturing depending on the goods produced.

When items are manufactured in batches with unique batch numbers allotted to each batch. Production planning in batches helps run machinery in a well-planned manner as the next step is planned and the machines are allocated accordingly.

This type of production planning is common in job shops where custom material processing requirements are carried out. Each production plan will most likely be different from the last with the use of different materials, machinery, and operations on the materials.

In flow method, materials are processed smoothly from one machine to the next with very little human intervention. Any waiting time or bottlenecks are removed so that the materials ‘flow’ continuously till they become finished goods. Standardized work and quality control are essential to ensure consistent quality when producing items with the flow method.

5. Topics around production planning

5.1 production planning and control.

Production planning is about planning resources for delivering products and production control is about controlling the production system to achieve targets optimally. Production control has more to do with monitoring the production line and taking corrective action where things are not moving as planned.

‘Production planning and control’ is simply applying both these concepts to get an efficient production line.

Let’s understand the benefits of using both these methods together:

- Better organization for on-time delivery to customers

- Optimum resource utilization

- Less investment in inventory

- Avoid resource wastage

- Increased efficiency, hence reduced costs

- Improved quality by catching and reducing defects

Now let’s look at these topics individually to further distinguish between them.

5.1.1 Production planning

The steps involved in production planning are:

- Planning : This involves planning shop floor resources to deliver finished goods on time.

- Routing : The exact route/path or set of operations the materials go through is known as a routing. Finding optimum routes that reduce wastage and promote continuous flow is a part of production planning. Finding better routings is about using workstations, machines, and workers in different orders without affecting the product to deliver the items faster.

- Scheduling : The machines, activities, and workers are scheduled to do tasks that are a part of the production plan. Scheduling well helps in delivering the finished products on time.

- Loading : Loading here refers to overloading the production line to see how much it can handle. By loading each point, the last bits of efficiency can be squeezed to get the maximum value.

5.1.2 Production control

The steps involved in production control are:

- Dispatching : After the production plan is ready it’s time to implement it by dispatching items in and out of the production line. Different operations and the corresponding workstations are managed to dispatch items to them. The time to complete each activity or ‘job’ is recorded.

- Followup : After issuing a plan, bottlenecks and other problems may arise. Follow-ups are done by supervisors to eliminate any bottlenecks and ensure that things are going according to plan.

- Inspection : Routine inspections are done during production to verify that the materials are being processed correctly. Note that this is different from quality inspections which are done after the product is finished.

- Correction : The results from other steps in production control are reviewed and corrections are made where necessary. This includes the routings, scheduling work, and even conversations with workers who are taking those long breaks.

5.2 Production planning and inventory control

An indispensable part of manufacturing is managing your inventory. Controlling inventory is an essential part of production planning. Proper inventory control involves ensuring an adequate supply of raw materials which results in the timely delivery of products. It also minimizes the overstocking of finished products. Maintaining both—proper inventory levels and accurate data—helps in good production planning.

5.3 Production planning vs production scheduling

Production planning is about planning the number of resources needed to finish multiple manufacturing orders. Production scheduling is about timing the activities, machines, and workers right to run the production process. The work and workloads are optimized in production scheduling. There are two ways production scheduling is performed:

- Forward scheduling : Say, if resources are available today, plan from today till the order due date.

- Backward scheduling : If the availability date of resources is not certain, plan from the due date backward to a number of days.

Production scheduling levels the inventory, labor, and helps in estimating delivery dates accurately.

6. Production planning in ERP software

A production plan can be created and managed easily by using ERP software. You’d need the items, bill of materials, routings, customer orders, and material requests ready before creating a production plan.

6.1 Creating the production plan

Once you have the prerequisite records ready, it’s time to create the production plan. Let’s follow through step by step.

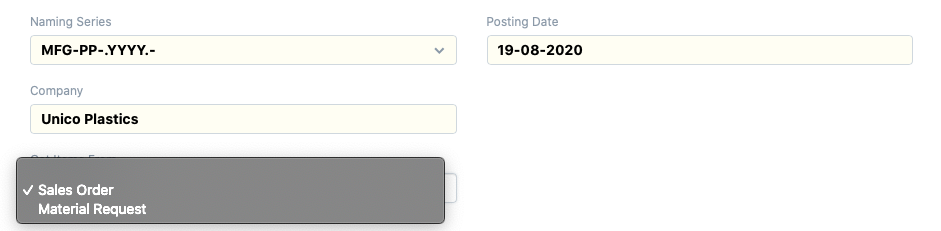

If the items to produce have been requested via a customer order or material requisitions, they can be fetched into the production plan.

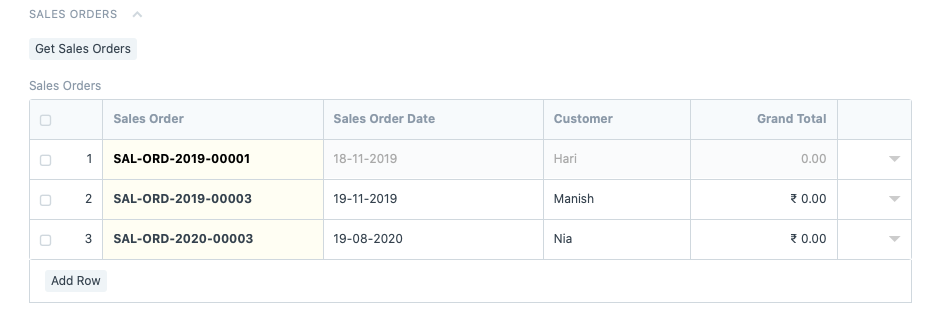

By clicking on ‘Get Sales Orders’, either multiple orders or multiple requests can be fetched here, like this:

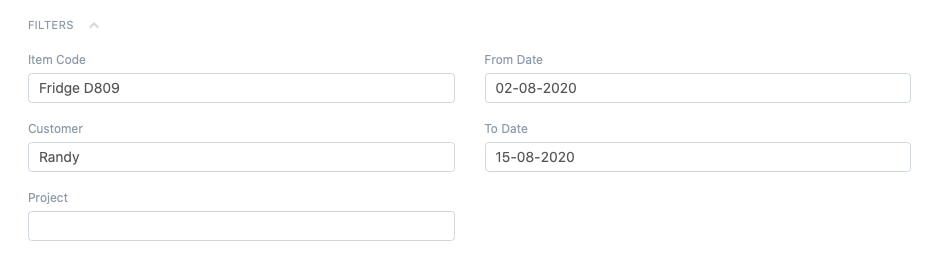

If you have a ton of orders or requests, set filters to narrow down your search like this:

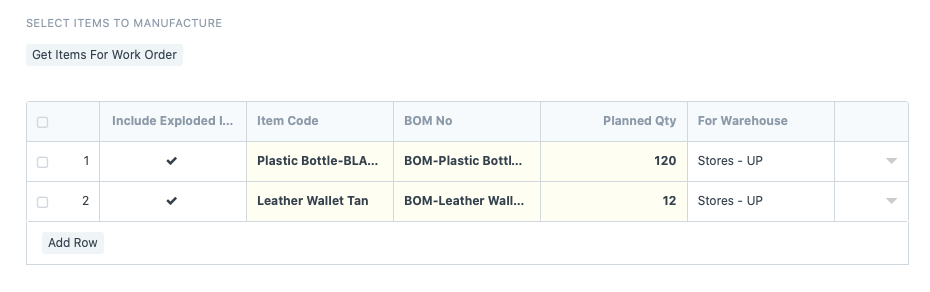

Now, by clicking on ‘Get Items for Work Order’, the items to be manufactured using the current production plan will be fetched. The quantities can be increased in case you want to account for SKUs. It’s a good idea to keep extra inventory for items that take a very long time to manufacture but have predictable, fast demands.

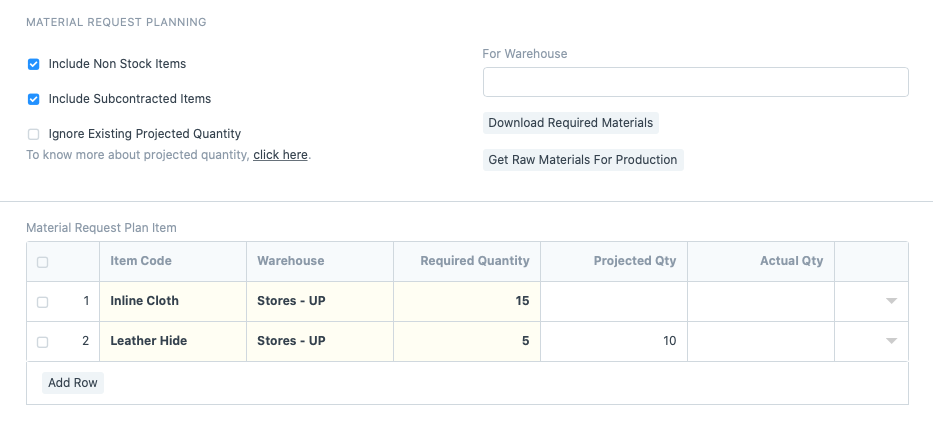

Now that you know what items to manufacture since the bill of materials has been fetched, it’s time to plan for the raw materials. Clicking on ‘Get Raw Materials for Production’ will fetch all the raw materials and sub-assemblies required for manufacturing. If the inventory levels are present in the warehouses, they’ll not be fetched here. Click on ‘Download Required Materials’ to download the raw material list as a spreadsheet, send it to others or print it.

Some options to note here are:

- Including non-stock items in case you want to account for some external items that you don’t store in your inventory but will be used in production.

- Some subassemblies may be subcontracted, you can choose to include or exclude them in your plan. The choice here depends on whether the subcontracting is for operations or assembly among other factors.

- Projected quantity will show the inventory levels that should be produced based on demands and requests. If you want to ignore this number and produce quantities that you see fit, go ahead and tick the ‘Ignore Existing Projected Quantity’ checkbox.

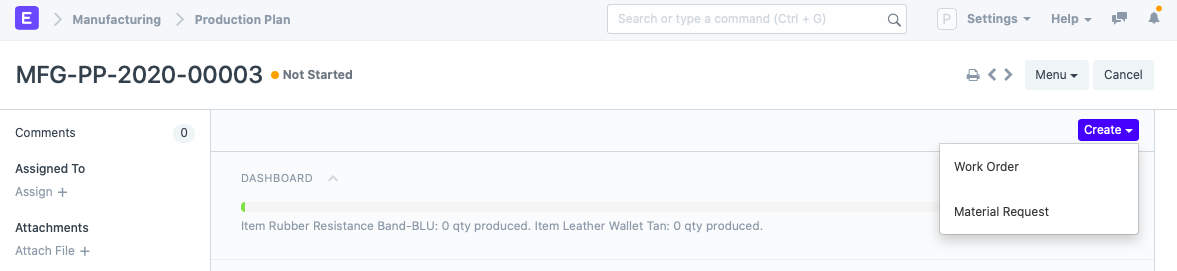

- Finally, you submit and start with the production plan. Then, from the production plan work orders can be created. One work order for each BOM will be created if you click on ‘Create > Work Order’.

In the work order, the quantity to be produced can be changed depending on whether you want to produce some quantities later. Work orders are used by shop floor supervisors.

From the work orders, job cards are created to record the operations on raw materials. The jobs/operations are done at different workstations/machines.

Once the ‘jobs’ are done on the materials and items are processed, the work order is complete.

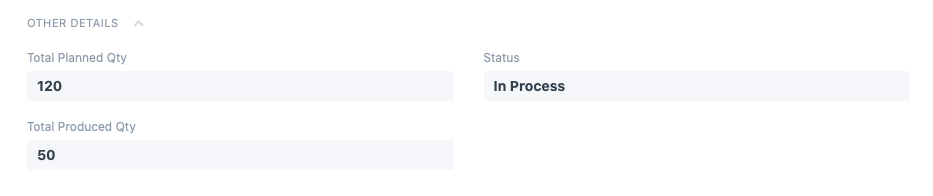

Now, depending on the quantity of items produced, the following details can be seen in the last section of the production plan:

6.2 Scheduling the plan

Creating a production plan is one part of the planning process, the other is scheduling different resources to the production plan. Factors like machine downtime, workstation capacity, and availability of raw materials are taken into consideration when scheduling.

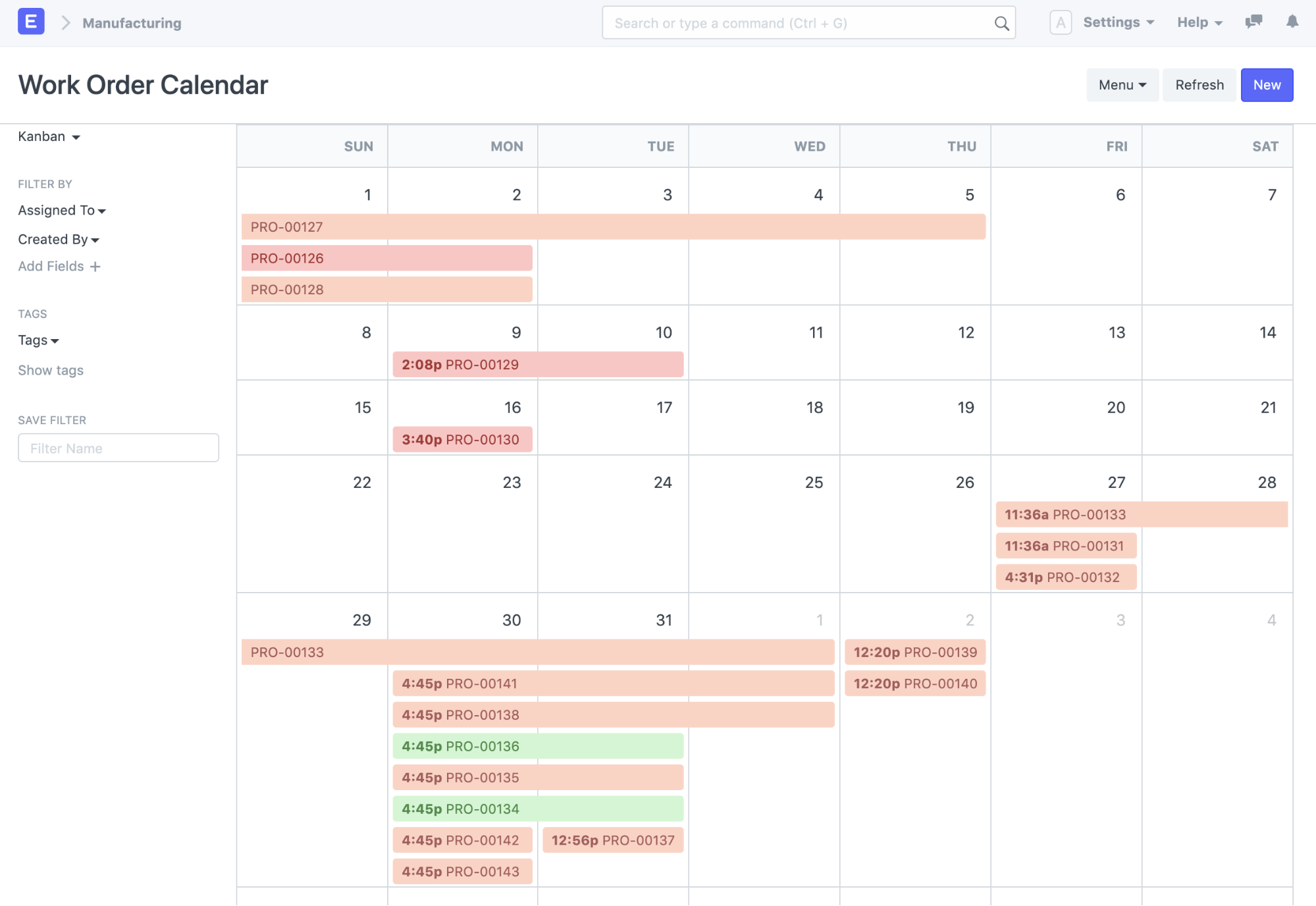

In ERPNext, capacity planning is enabled by default. If you go to the calendar from the work order list, you can see the workstations for which materials are transferred and work has started (orange), neither materials are transferred nor work has started (red), and the ones that have been completed (green).

6.3 Role of project management in production planning

In larger organizations with multiple orders or when you get a large project from a client to produce hundreds of different items, project management comes handy. By using a project in ERPNext, you can create multiple work orders against it to track them all from one place.

That's it. Production planning is done easily with the right tools. By allocating resources carefully, planning for inventory, and avoiding mistakes, you can deliver you orders on time.

First, we introduced what a production plan is and discussed its importance. Then, we talked about the important things to note before creating a production plan and talked about the common mistakes to avoid when planning. Further, we talked about the types of production plans and the role of software in production planning.

For a monthly digest of such blogs and more updates, subscribe to our newsletter .

- Production planning

- Methods of production

- Scheduling (production processes)

ERPNext documentation

- Production Plan

- Capacity Planning

- Operations: Methods of Production (Overview) | Business | tutor2u

- Production plan: Top tips for improving your operations

- Grace college production planning

Prasad Ramesh

Marketing at Frappe.

Thank you very much for your informative info on production planning as I really need to use as guidance for my job as production planner

We are extremely impressed with this article because it contains a lot of great information. We, at MGH Distributors, are a part of the Import and distribution business. Our food products include Candies, cakes, cooking oil, beverages, jelly products, cookies and many more. The FMCG range brings to you world-class razors, blades, bar soaps. Visit our website to know more

Thank you for this very good overview on production in ERPNext.