This site uses cookies to improve your experience. By viewing our content, you are accepting the use of cookies. To help us insure we adhere to various privacy regulations, please select your country/region of residence. If you do not select a country we will assume you are from the United States. View our privacy policy and terms of use.

- Inventory Management Software

- Forecasting

- Sustainability

- Supply Chain Visibility

AI in the Retail Industry: Benefits, Case Studies & Examples

MARCH 27, 2024

Other Examples of AI in the Retail Industry AI in the retail industry is helping improve customer experiences on one hand and operational workflows on the other. The post AI in the Retail Industry: Benefits, Case Studies & Examples appeared first on ThroughPut. The result was significant: savings of €3-6.5

Supply Chain – Finance Connection: A Supply Chain Improvement Case Study

APRIL 27, 2021

Supply Chain – Finance Connection: A Supply Chain Improvement Case Study was first posted on April 27, 2021 at 7:57 am. This is a different approach to begin the journey of financial improvement using supply chain improvement projects.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Trending Sources

Talking Logistics

- Enterra Insights

Logistics Viewpoints

- The Logistics of Logistics

- Enchange Supply Chain Consultancy

L’Oréal: A Case Study in Supply Chain Excellence

Supply Chain Shaman

OCTOBER 5, 2018

to This is an example of managing a balanced portfolio and of driving a supply chain revolution. This case study is the best example we have seen of a customer-centric supply chain. In China, for example , more than 40% of the company’s business through eCommerce. L’Oréal’s Performance Compared to the Peer Group.

Easy Supply Chain Savings: A Simple Supply Chain Case Study

Logistics Bureau

AUGUST 31, 2021

Supply Chain & Logistics case studies are always interesting. Maybe you have some similar examples you can share in the comments? Check out this article related to this topic: 7 Mini Case Studies : Successful Supply Chain Cost Reduction and Management. And it was an easy problem to fix!

How to Package and Price Embedded Analytics

Advertisement

Just by embedding analytics, application owners can charge 24% more for their product. How much value could you add? This framework explains how application enhancements can extend your product offerings. Brought to you by Logi Analytics.

Supply Chain Case Study: the Executive's Guide

Supply Chain Opz

JUNE 1, 2014

Analysis of case study is certainly one of the most popular methods for people from business management background. In order to accelerate the learning, this article has gathered 20+ most sought-after supply chain case studies , analyzed/categorized them by industry and the findings are presented.

Is Apple Supply Chain Really the No. 1? A Case Study

JANUARY 7, 2013

Case Studies . A Case Study . Everything about Apple Inc is the talk of the town, for example , the new Ipad, Iphone, Apple Map or even the environmental and labor issues at its suppliers facilities. To get a closer look at the modern day supply chain at Apple Inc, this case study utilizes content analysis technique.

Alternative Protein: A Food Manufacturers Guide [+ Case Study]

AUGUST 12, 2021

How food manufacturers are taking advantage of the alternative protein trend: A case study One recently launched New Zealand company, Food Nation , is proving a winner in the alternative protein space. French company Ynsect, for example , farms mealworms to produce food products for humans and animals.

AI in the Food Industry: Case Studies, Challenges & Future Trends

MARCH 28, 2024

Case Studies of Successful AI Integration in Food Supply Chain Church Brothers Farms Church Brothers Farms, a family-owned vegetable business with a vast cultivation area of 40,000 acres, faced significant challenges due to product perishability, volatile market conditions and logistical issues, among others.

Real-Time Trackers: A Welcome Labor Solution for Logistics

Real-life case study examples of how real-time tracking helped two leading logistics providers overcome the challenges of the growing labor shortage. Why streamlining data simplifies the logistics role. The difference between real-time data tracking vs. passive data logging, and why the former is key to efficient operations.

Thoughts. Selecting Supply Chain Software

APRIL 29, 2024

For example , those that actively read my blog, know that I frequently take issue with SAP, but seldom with Oracle. For example , how do you compare Arkieva to ToolsGroup ? Then build business case studies (think back to your business school case studies ) describing the opportunity. The reason? Avoid pitfalls.

Machine Learning in Supply Chain: Definition, Uses, Case Studies

APRIL 4, 2023

We also break down several case studies of companies currently using machine learning in their supply chain processes. For example , if your customers buy large quantities of a certain product, machine learning software will be able to identify the surge in demand and feed the information back to the inventory management systems.

Lionel Racing: An Omni-Channel Case Study

JULY 19, 2016

For example , “many of our Direct-to-Consumer [drop ship] customers want everything branded as if the order is coming from them even though it’s coming from our facility,” explained Gemereth. The post Lionel Racing: An Omni-Channel Case Study appeared first on Talking Logistics with Adrian Gonzalez.

BASF Video Case Study: The Value of Real-Time Freight Visibility

MAY 3, 2018

In addition to improved customer satisfaction, Wehrle shared these examples : The data we’re getting has been hugely successful. The post BASF Video Case Study : The Value of Real-Time Freight Visibility appeared first on Talking Logistics with Adrian Gonzalez. Benefits of Real-Time Freight Visibility.

What are Dark Stores, and How do they Work? [+ case studies]

NOVEMBER 3, 2021

Here we look at how dark stores operate, how they’re profitable and why they’re on the rise – along with four examples to showcase dark stores in action. The Gorillas example shows how potential regulations to protect workers and how those workers are treated will also figure into the mix.

TMS for SMB: A Case Study with Carhartt

OCTOBER 19, 2016

Carhartt is a great example . At the end of the day, the best approach is making the effort to truly understand and address the unique needs and characteristics of every company — both today and where they’re aiming to be in the future. Gibson highlighted in her presentation, Carharrt is experiencing rapid growth.

Cross Docking 101: What, Why and How? [with case studies]

SEPTEMBER 23, 2021

Time to deliver goods Cross docking can add additional time to the delivery process compared to, for example , a direct shipment strategy that involves the direct transfer to the end customer. Three case studies Cross docking strategies are used around the world and across different industries. Who uses cross docking?

Redesign to Improve Value: A Case Study of a Supply Chain Leader

JUNE 21, 2014

For example , we discovered that transportation and duties are 5x the expense of labor and overhead. For example , people want prestige beauty from the US, Europe or Japan. Take another example – few people know where their TV was made, but the buyer cares greatly about the reliability of that product. It wasn’t that easy.

How Food Manufacturing Software Drives Profit [w Case Studies]

AUGUST 11, 2020

For example Stock Age by Stock Keeping Unit (SKU) can be cross-referenced with warehouse location to see which ingredients are sitting on the shelf and need to be moved (perhaps with a local promotion or price change). CASE STUDY 1: Gourmet Organic Herbs. CASE STUDY 2: Brandini Toffee.

Trying to Push Content Above the Noise

JANUARY 2, 2024

Many discussions focus on driving improvement through planning, yet, when I take the client case studies on the websites of leading planning technologies and map the intersection of operating margin and inventory turns, I do not see metric improvement, sustained performance, or an increase in value. It is just accepted.

8 Examples of Kanban in Lean Manufacturing

MARCH 2, 2022

Here we give you eight real-world examples of how businesses use Kanban, a popular lean tool that’s helped companies in a huge range of sectors improve efficiency – especially those in the manufacturing industry. If you already know what Kanban is and just want the case studies , scroll down! Software development is an example .

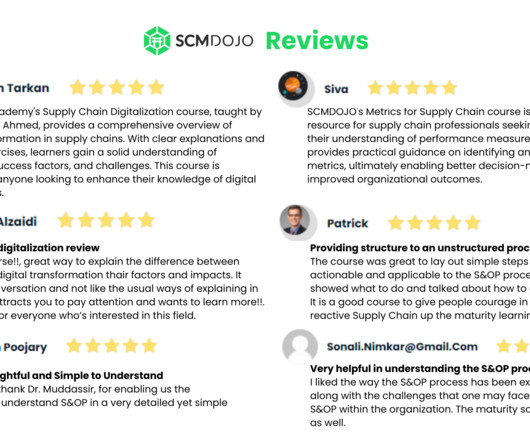

SCMDOJO vs CSCP Supply Chain Certification: My Personal Experience as a Supply Chain Professional

OCTOBER 8, 2024

It covers concepts in detail but offers very little in terms of practical exercises, real-world case studies , or detailed models. SCMDOJO offers an abundance of case studies , detailed models, and exercises that simulate the challenges professionals face daily. In comparison, SCMDOJO was designed to fill this gap.

Client Case Study Video Interview

APRIL 19, 2019

Client Case Study Video Interview with Lucid Motors, Menlo Park, CA. For example , certain areas were not quite to our liking and some of the formatting we wanted to change and you were quick to do that and it made our senior management very happy. Q: Can you give me one example of how the system has saved you time and effort ?

[PODCAST] The Growing “Influence” of Content Marketing in the Supply Chain

GlobalTranz

MARCH 3, 2020

Business and Marketing Resources Marketing Logistics Services: A Discussion on Getting Attention Online Listen to the Podcast Example of an Effective Transportation Management Case Study View Case Study How Industrial Companies Can Pivot to Inbound Organizations & Increase Customer Experience Listen.read More.

Make Room for Leadership to Drive S&OP

MAY 13, 2024

For example , in the research, I found maturity in Cadbury, DuPont, and Gilette processes. One of my favorite case studies was Campbells in 2014. See the World Kitchen case study in the Agility Report. This research, completed in 2006, was during the transformation of multi-national to global supply chains.

The Green Corridor: Saving Whales in California – A Case Study in Regional Collaboration

The Logistics & Supply Chain Management Society

AUGUST 19, 2022

The Green Corridor: Saving Whales in California – A Case Study in Regional Collaboration. This story is a great example of how, collaboration can happen in our fractured and decentralized commercial environment. The Green Corridor: Saving Whales in California – A Case Study in Regional Collaboration.

Surgery Center Case Study: Less Time at Computer, More Time in OR

FEBRUARY 6, 2019

We now know, on a real-time basis, whether a contract has expired, for example . The post Surgery Center Case Study : Less Time at Computer, More Time in OR appeared first on Hybrent. In addition, Hybrent ensures we’re staying in compliance on contracts. Ready to Update Your Supply Chain? Request a Demo.

Understanding the Profitability of Omnichannel Retail is a Problem

NOVEMBER 20, 2023

But one thing you notice as you go to omnichannel software vendor’s web sites and examine customer case studies , the case studies may talk about retailers growing their revenues by 100% or more, but none talk about how much profitability grew. These new order fulfillment paths allowed retailers to rapidly grow sales.

Examples of How Supplier Quality Management System Implementations Pay Off

JUNE 11, 2015

We conclude our series on supplier quality management (SQM) today with a look at some case studies and examples of benefits derived from the application of a supplier quality management system. Examples and Case Studies from the Implementation of a Supplier Quality Management System.

Ensemble Forecasting: The Difference Between Staying Ahead or Falling Behind

AUGUST 19, 2024

In this article, we delve into the benefits of employing ensemble modeling for demand forecasts, backed by examples and data. Example : Consider a retail company that experiences sudden demand spikes during holiday seasons. For example During the COVID-19 pandemic, demand patterns underwent rapid and unprecedented changes.

A Case Study in Reverse Logistics Optimization!

Supply Chain Game Changer

NOVEMBER 23, 2018

“This has been an excellent example of how ModusLink can deliver measurable value for our computing and hardware clients,“ explains ModusLink’s Vice President of Global Client Development. The post A Case Study in Reverse Logistics Optimization! Learn more at [link]. Check out Reverse Logistics and the Power of Your 3PL!

JAGGAER Webinar with Accenture Strategy and Attijariwafa Bank Case Study: Accelerating Trust in Banking – Internal, Suppliers and Customers

OCTOBER 22, 2020

A case study presentation by Youness Taghrichte provided a good example of how JAGGAER customers in the financial services sector are tackling these issues. Attijariwafa Bank has successfully implemented a source-to-contract solution with the JAGGAER ONE platform.

Melitta: Collaborating for an Improved Forecasting Process

NOVEMBER 2, 2020

For example , within an audit workflow multiple stakeholders across various regions can apply detailed market knowledge specific to their regions to the demand baseline forecast for a more accurate result. Read the full Melitta case study below. Read Case Study . Michael Youssef.

Elevating The Voice of the Supply Chain Contrarian

JUNE 21, 2023

Many of the case studies being presented at today’s conferences were born during the pandemic and the post-pandemic turbulence. For example , Monster Beverages beats Coca-Cola and PepsiCo, while Celanese outperforms Dow Chemical. While companies talk digital, the projects follow traditional supply-centric paths.

New Case Study on Alcatel-Lucent Sustainable Procurement Best Practices

JULY 9, 2015

Case Study . We are pleased to publish a new case study detailing Alcatel-Lucent’s sustainable procurement program. Download the Case Study from the library. Long-time EcoVadis client, Alcatel-Lucent, has done all this and more.

Unlocking the Value of Global Supply Chain: the Case Studies

JULY 7, 2014

For example , they make it easier for customers to locate products during shopping, pick the products, checkout, bringing products back home and install the furniture. Their unique selling points are products with good design at lower prices. To drive cost down, Ikea shifts some of their activities to customers or self service operating model.

Cost to Serve Case Study that was Off the Scale! – with Steven Thacker

JULY 21, 2020

A Great Example . Let us watch the video below: Related articles on this topic have appeared throughout our websites, why not check them out? Robobyrne: Cost To Serve Lesson. Supply Chain Secrets: What is Cost to Serve? – Best Regards, Rob O’Byrne. Email: [email protected]. Phone: +61 417 417 307.

Case Study: How Generac Power Systems Cut Millions from Its Global Transportation Spend

CH Robinson Transportfolio

MARCH 28, 2018

For example , Generac works with our global forwarding and port services experts to optimize containerized freight moving from the West Coast to Chicago and beyond. The post Case Study : How Generac Power Systems Cut Millions from Its Global Transportation Spend appeared first on Transportfolio.

The Green Corridor: To Realise the Circular Economy Dream – Reach Out to Your Community

NOVEMBER 22, 2022

In one example , Crust Group in Singapore provides a Southeast Asian example of a cross industry “circular economy” partnership. In my compost example , I save on buying fertilizer (along with all the processing, packaging and transportation associated with it). This is the challenge that industries face all around the world.

The Critical Path: Navigating Supply Chain Efficiency in the Oil Industry

JUNE 27, 2024

Crisis Management Strategies for Unforeseen Disruptions Developing robust crisis management frameworks ensures that companies can respond swiftly and effectively to supply chain disruptions.

The Best Websites To Learn Supply Chain

NOVEMBER 17, 2024

Pros Cons Expert Monitoring No free practical tools Availability of newsletter No free podcasts Highly theoretical Offer less practical & real-world examples Read More About CIPS onDemand VS SCMDOJO Here Udemy Similarly, Udemy offers a wide range of courses that need more structure.

Optimization and Execution: How Manufacturing can lead the Industry Renaissance

DELMIA Quintiq

JUNE 9, 2020

Companies that were unable to meet these challenges have been left behind (for example , in High Tech think Blackberry and Compaq). In numerous case studies , manufacturers have found that the limited visibility to shop floor activities and poor planning led to problems with over-scheduled machinery and equipment.

LinkedIn Learning vs SCMDOJO: Which Online Learning Platform is Right for You?

MAY 27, 2024

The courses are designed to provide practical skills with real-world examples , case studies , and exercises, allowing you to apply what you learn in your professional life. SCMDOJO’s interactive learning features, such as quizzes and case studies , are seamlessly integrated into the platform.

Stay Connected

Join 102,000+ Insiders by signing up for our newsletter

- Participate in Supply Chain Brief

- How to achieve six-figure benefits from digitizing paper-based supply chain operation

- 2019 Supply Chain Brief Summer Reading List

- Stay At Home Reading List

- Add a Source

- Add a Resource

- 2018 Supply Chain Brief MVP Awards

- 2019 Supply Chain Brief MVP Awards

- 2020 Supply Chain Brief MVP Awards

- 2021 Supply Chain Brief MVP Awards

- 2022 Supply Chain Brief MVP Awards

- Wed. Nov 20

- Tue. Nov 19

- Mon. Nov 18

- Sun. Nov 17

- Nov 09 - Nov 15

- Warehousing

- Procurement

- Transportation

- Supply Chain

- More Topics

Input your email to sign up, or if you already have an account, log in here!

Enter your email address to reset your password. a temporary password will be e‑mailed to you., be in the know on.

Supply Chain Brief

Expert insights. Personalized for you.

We organize all of the trending information in your field so you don't have to. Join 102,000+ users and stay up to date on the latest articles your peers are reading.

Get the good stuff

Subscribe to the following Supply Chain Brief newsletters:

You must accept the Privacy Policy and Terms & Conditions to proceed.

You know about us, now we want to get to know you!

Check your mail, we've sent an email to . please verify that you have received the email..

We have resent the email to

Let's personalize your content

Use social media to find articles.

We can use your profile and the content you share to understand your interests and provide content that is just for you.

Turn this off at any time. Your social media activity always remains private.

Let's get even more personalized

Choose topics that interest you., so, what do you do.

Are you sure you want to cancel your subscriptions?

Cancel my subscriptions

Don't cancel my subscriptions

Changing Country?

Accept terms & conditions.

It looks like you are changing your country/region of residence. In order to receive our emails, you must expressly agree. You can unsubscribe at any time by clicking the unsubscribe link at the bottom of our emails.

You appear to have previously removed your acceptance of the Terms & Conditions.

We noticed that you changed your country/region of residence; congratulations! In order to make this change, you must accept the Aggregage Terms and Conditions and Privacy Policy. Once you've accepted, then you will be able to choose which emails to receive from each site .

You must choose one option

Please choose which emails to receive from each site .

- Update All Sites

- Update Each Site

Please verify your previous choices for all sites

Sites have been updated - click Submit All Changes below to save your changes.

We recognize your account from another site in our network , please click 'Send Email' below to continue with verifying your account and setting a password.

You must accept the Privacy Policy and Terms & Conditions to proceed.

This is not me

Photo: Pixabay/geralt

7 mini case studies: successful supply chain cost-reduction and management

Rob O'Byrne

Group Managing Director - Logistics Bureau

If you were to tell me that your company had never looked at its supply chain costs and sought to deliver reductions, I would be mightily surprised. On the other hand, if you told me your company hasn’t been able to sustain any progress in supply chain cost reduction, I wouldn’t be surprised at all.

Most companies begin with the best intentions to achieve successful and sustainable supply chain cost management, but somehow seem to lose momentum, only to see costs increase again in short order.

The following seven mini case studies explore a few high-profile companies that have managed to sustain their supply chain cost-reduction efforts and keep expenses under control. The challenges faced by these organisations and the steps they took, may provide some inspiration for successful long-term cost management within your organisation.

1. Deere & Company

Deere & Company (brand name John Deere) is famed for the manufacture and supply of machinery used in agriculture, construction, and forestry, as well as diesel engines and lawn care equipment. In 2014, Deere & Company was listed 80th in the Fortune 500 America’s ranking and was 307th in the 2013 Fortune Global 500 ranking.

Supply Chain Cost Reduction Challenges: Deere and Company has a diverse product range, which includes a mix of heavy machinery for the consumer market, and industrial equipment, which is made to order. Retail activity is extremely seasonal, with the majority of sales occurring between March and July.

The company was replenishing dealers’ inventory weekly, using direct shipment and cross-docking operations from source warehouses located near Deere & Company’s manufacturing facilities. This operation was proving too costly and too slow, so the company launched an initiative to achieve a 10% supply chain cost reduction within four years.

The Path to Cost Reduction: The company undertook a supply chain network-redesign program, resulting in the commissioning of intermediate “merge centers” and optimization of cross-dock terminal locations.

Deere & Company also began consolidating shipments and using break-bulk terminals during the seasonal peak. The company also increased its use of third-party logistics providers and effectively created a network that could be optimized tactically at any given point in time.

Supply Chain Cost Management Results: Deere & Company’s supply chain cost-management achievements included an inventory decrease of $1 billion, a significant reduction in customer delivery lead times (from ten days to five or less) and annual transportation cost savings of around 5%.

One of the world’s largest manufacturers of computer chips, Intel needs little introduction. However, the company needed to reduce supply chain expenditure significantly after bringing its low-cost “Atom” chip to market. Supply chain costs of around $5.50 per chip were bearable for units selling for $100, but the price of the new chip was a fraction of that, at about $20.

The Supply Chain Cost Reduction Challenge: Somehow, Intel had to reduce the supply chain costs for the Atom chip, but had only one area of leverage—inventory.

The chip had to work, so Intel could make no service trade-offs. With each Atom product being a single component, there was also no way to reduce duty payments. Intel had already whittled packaging down to a minimum, and with a high value-to-weight ratio, the chips’ distribution costs could not be pared down any further.

The only option was to try to reduce levels of inventory, which, up to that point, had been kept very high to support a nine-week order cycle. The only way Intel could find to make supply chain cost reductions was to bring this cycle time down and therefore reduce inventory.

The Path to Cost Reduction: Intel decided to try what was considered an unlikely supply chain strategy for the semiconductor industry: make to order . The company began with a pilot operation using a manufacturer in Malaysia. Through a process of iteration, they gradually sought out and eliminated supply chain inefficiencies to reduce order cycle time incrementally. Further improvement initiatives included:

- Cutting the chip assembly test window from a five-day schedule, to a bi-weekly, 2-day-long process

- Introducing a formal S&OP planning process

- Moving to a vendor-managed inventory model wherever it was possible to do so

Supply Chain Cost Management Results: Through its incremental approach to cycle time improvement, Intel eventually drove the order cycle time for the Atom chip down from nine weeks to just two. As a result, the company achieved a supply chain cost reduction of more than $4 per unit for the $20 Atom chip—a far more palatable rate than the original figure of $5.50.

3. Starbucks

Like Intel, Starbucks is pretty much a household name, but like many of the most successful worldwide brands, the coffee-shop giant has been through its periods of supply chain pain. In fact, during 2007 and 2008, Starbucks leadership began to have severe doubts about the company’s ability to supply its 16,700 outlets. As in most commercial sectors at that time, sales were falling. At the same time, though, supply chain costs rose by more than $75 million.

Supply Chain Cost Reduction Challenges: When the supply chain executive team began investigating the rising costs and supply chain performance issues, they found that service was indeed falling short of expectations. Findings included the following problems

- Fewer than 50% of outlet deliveries were arriving on time

- Several poor outsourcing decisions had led to excessive 3PL expenses

- The supply chain had, (like those of many global organisations) evolved, rather than grown by design, and had hence become unnecessarily complex

The Path to Cost Reduction: Starbucks’ leadership had three main objectives in mind to achieve improved performance and supply chain cost reduction. These were to:

- Reorganize the supply chain

- Reduce cost to serve

- Lay the groundwork for future capability in the supply chain

To meet these objectives, Starbucks divided all its supply chain functions into three main groups, known as “plan” “make” and “deliver”. It also opened a new production facility, bringing the total number of U.S. plants to four.

Next, the company set about terminating partnerships with all but its most effective 3PLs . It then began managing the remaining partners via a weekly scorecard system, aligned with renewed service level agreements.

Supply Chain Cost Management Results: By the time Starbucks had completed its transformation program, it had saved more than $500 million over the course of 2009 and 2010, of which a large proportion came out of the supply chain, according to Peter Gibbons, then Executive Vice President of Global Supply Chain Operations.

Like Deere & Company, AGCO is a leading global force in the manufacture and supply of agricultural machinery. The company grew substantially over the course of two decades, achieving a considerable portion of that growth by way of acquisitions.

As commonly happens when enterprises grow in this way, AGCO experienced increasing degrees of supply chain complexity, along with associated increases in cost, but for many years, did little to address the issue directly, primarily due to the decentralized and fragmented nature of its global network.

In 2012, AGCO’s leaders recognised that this state of affairs could not continue and decided to establish a long-term program of strategic optimisation.

Supply Chain Cost Reduction Challenges: With five separate brands under its umbrella, AGCO’s product portfolio is vast. At the point when optimisation planning began, sourcing and inbound logistics were managed by teams in various countries, each with different levels of SCM maturity, and using different tools and systems.

As a result of the decentralised environment, in which inbound logistics and transport management were separate operational fields, there was insufficient transparency in the supply chain. The enterprise as a whole was not taking advantage of synergies and economies of scale (and the benefits of the same). These issues existed against a backdrop of a volatile, seasonal market.

The Path to Cost Reduction: Following a SCOR supply chain benchmarking exercise, AGCO decided to approach its cost reduction and efficiency goals by blending new technology—in the form of a globally integrated transport management system (TMS)—with a commitment to form a partnership with a suitably capable 3PL provider.

As North and South American divisions of the company were already working with a recently implemented TMS, leaders decided to introduce the blended approach in Europe, with commitments to replicate the model, if successful, in its other operating regions.

With the technology and partnership in place, a logistics control tower was developed, which integrates and coordinates all daily inbound supply activities within Europe, from the negotiation of carrier freight rates, through inbound shipment scheduling and transport plan optimisation to self-billing for carrier payment.

Supply Chain Cost Management Results: Within a year and a half of their European logistics solution’s go-live, AGCO achieved freight cost reductions of some 18%, and has continued to save between three and five percent on freight expenditure, year-on-year, ever since. Having since rolled the new operating model out in China and North America, the company has reduced inbound logistics costs by 28%, increased network performance by 25% and cut inventory levels by a quarter.

Headquartered in Westport Connecticut, Terex Corporation may not be such a well-known name, but if your company has ever rented an aerial working platform (a scissor-lift or similar), there is a good chance it was manufactured by Terex and dispatched to the rental company from its transfer center in North Bend, Washington.

The North Bend facility is always full of lifting equipment. The company makes most pieces to order and customizes them to meet customers’ unique preferences. Terex maintained a manual system for yard management at the transfer centre, which generated excessive costs for what should have been a relatively simple process of locating customers’ units to prepare them for delivery.

The Supply Chain Cost Reduction Challenge: A wallboard and sticker system was a low-tech solution for identifying equipment items in the yard at Terex. While inexpensive in itself, the solution cost around six minutes every time an employee had to locate a unit in the yard. It also required a considerable number of hours to be spent each month taking physical inventories and updating the company’s ERP platform.

The Path to Cost Reduction: Terex decided to replace the outdated manual yard management process with a new, digital solution using RFID tracking. Terex decided to replace the outdated manual yard management process with a new, digital solution using RFID tracking. Decision-makers chose a yard management software (YMS) product, and then had the transfer centre surveyed before initiating a pilot project covering a small portion of the yard.

After a successful pilot, the company approved the solution for full-scale implementation, replacing stickers, yard maps, and wallboard with electronic tracking and digital inventory management. As of December 2017, Terex was planning to integrate the yard management solution with its ERP platform to enable even greater functionality.

Supply Chain Cost Management Results: While the YMS cannot reconcile inventory automatically with the Terex ERP application, it does at least provide a daily inventory count via its business intelligence module. That alone has saved the labour costs previously incurred in carrying out manual counts.

More importantly, though, the RFID-based unit identification and location processes have saved the company around 70 weeks per year in labour costs, by cutting the process-time down from six minutes, to a mere 30 seconds per unit.

Avaya is a global force in business collaboration and communications technology, and not so many years ago, was operating what, by its own executives’ admission, was a worst-in-class supply chain. That situation arose as the result of multiple corporate acquisitions over a short space of time. The company was suffering from a range of supply chain maladies, including a long cash-to-cash cycle, an imbalance in supplier terms and conditions, excess inventory, and supply chain processes that were inefficient and wholly manual.

The Supply Chain Cost Reduction Challenge: After Avaya purchased Nortel Enterprise Solutions in 2009, the freshly merged company found itself but loosely in control of an unstable and ineffective supply chain operation. Aside from having too many disparate and redundant processes, the company had multiple IT solutions, none of which provided a holistic view of the supply chain or supported focused analysis.

The Path to Cost Reduction: Avaya’s senior management team realized that its technology solutions, which varied from being inadequate to inappropriate, were causing many of its problems. The various acquisitions and mergers had transformed Avaya into a different kind of enterprise, and what it needed, rather than a replacement for all the discrete systems, was one solution to tie them all together.

To that end, the company put its trust in cloud technology, which was relatively immature at the time, and migrated all processes onto one platform, which was designed to automate non-value-added activities and integrate those critical to proactive supply chain management, namely:

- Point of sale analysis

- Procurement analysis

- Supplier communication

- Supply and demand planning

- Inventory planning

- Inbound and outbound logistics planning

Of course, the technology was merely an enabler, and to transform its supply chain operation, Avaya embarked on a long-term, phased program to standardize processes, initiate a culture change, invest in top talent, and implement a system of rigorous benchmarking and KPI tracking .

Supply Chain Cost Management Results: Avaya’s program of transformation took place over a period of three to four years, between 2010 and 2014. The path to cost reduction was a long one, but ultimately successful.

By making a conscious effort to lead the enterprise into a new way of thinking, change business culture, and unify technology under a single platform, Avaya has improved inventory turns by more than 200%, reduced cash tied-up in stock by 94%, and cut its overall supply chain expenditure in half.

This dramatic turnaround also required the company to switch from a preoccupation with improving what it was doing, to a process of questioning what it was doing and why.

7. Sunsweet Growers

This final mini-case study in our collection, highlights how sometimes, excess supply chain costs are not about warehousing and transportation, but can be attributable to inefficiencies in manufacturing or production and—often at the root of it all—forecasting and planning.

Sunsweet Growers is the world’s biggest producer of dried fruits and a little over a decade ago, found that while it was managing distribution operations well, high production costs were inflating end-to-end supply chain expenditure.

The Supply Chain Cost Reduction Challenge: When the leadership at Sunsweet looked into the company’s production cost issues, recognition soon dawned that the distribution network was at least partly behind the problems. As a result, the company looked at how it could redesign the network to take out some of the production costs.

Later, it became apparent that although a redesign would yield some benefits, one of the most significant issues was in the approach to demand forecasting. Sunsweet was using a manual forecasting approach, with spreadsheets being the only technology involved.

The inefficiencies of this approach proved not only to hamper effective forecasting and production planning, but the knock-effect was an excess of warehouses in the network—so forecasting proved to be both a driver of production cost, and a key to improving the distribution network.

The Path to Cost Reduction: As in a number of the studies we’ve explored here, technology played a large part in solving Sunsweet’s problems. After evaluating some 30 different software solutions, the company finally settled on a supply chain planning suite, and planned its improvement program to make use of each of the solution’s modules in sequence, allowing ROI to be realized in phases as each module was implemented and leveraged.

At the same time, Sunsweet implemented a sales and operations planning program (S&OP) that once established, enabled plant resource requirements to be anticipated months—rather than weeks—in advance. As the overall improvement plan passed through its five phases, positive results accumulated and as hoped, software ROI reached 100% even before the company completed its full implementation.

Supply Chain Cost Management Results: Of course, the objective of Sunsweet’s improvement program was not merely to achieve a 100% return on investment in its supply chain planning platform. The aim was to reduce production costs, and although the company hasn’t published hard figures to quantify the total financial gain, it has claimed the following wins:

- A 15 to 20% increase in forecasting accuracy

- A reduction in overtime from 25% to 8% in production facilities

- A 30% reduction in finished-goods spoilage

- Number of warehouses in the United States cut from 28 to just eight

- A transportation cost-per-unit that remained static for two years despite increased utilization of costly refrigerated transport and rising fuel costs

From the achievements documented above, and highlighted in several industry publications and articles, you don’t need to be too much of a mathematician to deduce that cost savings would have been considerable.

Making Supply Chain Cost Reductions Stick

Of course, the above case studies are merely summaries of the changes these high-profile brands made to their supply chains. What can be seen from these brief accounts, though, is that for an enterprise to make significant and sustainable cost improvements, substantial change must take place.

- Deere & Company had to overhaul its network completely.

- Intel had to shift an entire supply chain to a new and previously unheard of strategy in its sector.

- Starbucks had to shake up its third-party relationships and increase production capacity.

- AGCO had to invest in technology and collaborative partnerships with external service providers.

- Terex had to implement costly (but effective) RFID tracking capabilities.

- Sunsweet Growers needed a best-of-breed software solution, and an S&OP program to improve forecasting and planning.

- Avaya needed to change company culture, implement cloud technology, rethink processes completely, and invest in the best supply chain talent it could find.

At the same time, none of the changes took place overnight. Each of the companies tackled issues in phases, effectively learning more as they went along.

You Won’t Find Savings in the Comfort Zone

When it comes to making supply chain cost reductions that stick, you should explore every avenue. However, at the root of high costs, there will usually be one major factor requiring innovation, whether it’s the network, inventory strategy, the working relationships with supply chain partners, or some other element of your operation.

Seldom do companies make decent savings by whittling away piecemeal at what seem, on the face of it, to be the most pressing issues of the day (such as direct transportation costs or supplier pricing).

If you want to see sustainable cost reductions, your company will need to view the big picture from a new angle or two, and be prepared to step outside of the comfort zone to which it will have become accustomed.

Rob O’Byrne is a supply chain consultant, coach and author with 40+ years experience in Supply Chain management. He is the expert making the blog called Logistics Bureau .

- # case studies

- # management

- # Supply Chain Management

- # T&L

IMAGES

VIDEO