- Data, AI, & Machine Learning

- Managing Technology

- Social Responsibility

- Workplace, Teams, & Culture

- AI & Machine Learning

- Organizational Culture

- Hybrid Work

- Big ideas Research Projects

- Artificial Intelligence and Business Strategy

- Responsible AI

- Future of the Workforce

- Future of Leadership

- All Research Projects

- Most Popular

- AI in Action

- Coaching for the Future-Forward Leader

- Culture Champions

- Measuring Culture

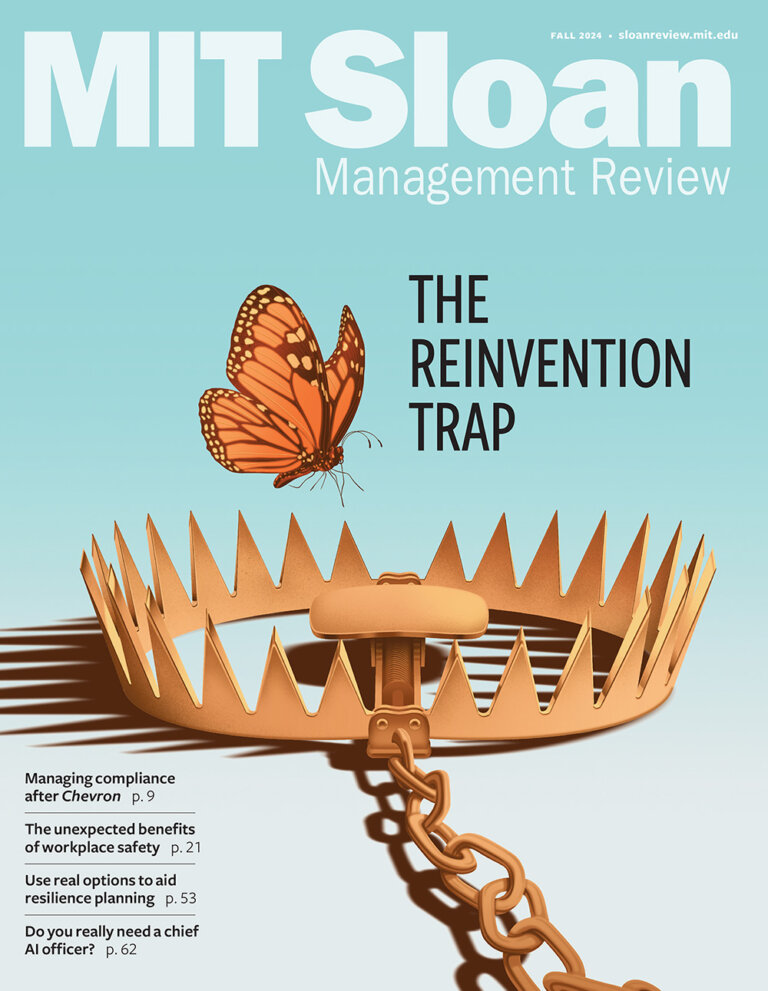

MIT SMR ’s fall 2024 issue highlights the need for personal and organizational resilience amid global uncertainty.

- Past Issues

- Upcoming Events

- Video Archive

- Me, Myself, and AI

Toyota’s Secret: The A3 Report

How toyota solves problems, creates plans, and gets new things done while developing an organization of thinking problem-solvers..

- Workplace, Teams, & Culture

- Innovation Strategy

- Quality & Service

- Organizational Behavior

While much has been written about Toyota Motor Corp.’s production system, little has captured the way the company manages people to achieve operational learning. At Toyota, there exists a way to solve problems that generates knowledge and helps people doing the work learn how to learn. Company managers use a tool called the A3 (named after the international paper size on which it fits) as a key tactic in sharing a deeper method of thinking that lies at the heart of Toyota’s sustained success.

A3s are deceptively simple. An A3 is composed of a sequence of boxes (seven in the example) arrayed in a template. Inside the boxes the A3’s “author” attempts, in the following order, to: (1) establish the business context and importance of a specific problem or issue; (2) describe the current conditions of the problem; (3) identify the desired outcome; (4) analyze the situation to establish causality; (5) propose countermeasures; (6) prescribe an action plan for getting it done; and (7) map out the follow-up process.

The leading question

Toyota has designed a two-page mechanism for attacking problems. What can we learn from it?

- The A3’s constraints (just 2 pages) and its structure (specific categories, ordered in steps, adding up to a “story”) are the keys to the A3’s power.

- Though the A3 process can be used effectively both to solve problems and to plan initiatives, its greatest payoff may be how it fosters learning. It presents ideal opportunities for mentoring.

- It becomes a basis for collaboration.

However, A3 reports — and more importantly the underlying thinking — play more than a purely practical role; they also embody a more critical core strength of a lean company. A3s serve as mechanisms for managers to mentor others in root-cause analysis and scientific thinking, while also aligning the interests of individuals and departments throughout the organization by encouraging productive dialogue and helping people learn from one another. A3 management is a system based on building structured opportunities for people to learn in the manner that comes most naturally to them: through experience, by learning from mistakes and through plan-based trial and error.

Get Updates on Transformative Leadership

Evidence-based resources that can help you lead your team more effectively, delivered to your inbox monthly.

Please enter a valid email address

Thank you for signing up

Privacy Policy

The A3s reproduced in this article represent just some of the stages in a typical development sequence — a process that may involve numerous iterations of the A3 before it is final. To illustrate how the A3 process works, we’ve imagined a young manager — call him Porter — who’s trying to solve a problem. The problem is that his Japan-based company is building a manufacturing plant in the United States, requiring many technical documents to be translated into English, and the translation project has been going badly. Porter uses the A3 process to attack the problem, which means that he gets coached through it by his boss and mentor — call him Sanderson. The A3s shown on these pages will give an idea of how one learning cycle might go, as Porter works on the problem under Sanderson’s tutelage. Porter’s first attempt at the A3 reveals, as early-stage A3s often do, his eagerness to get to a solution as quickly as possible.

(Editor’s note: The example is drawn from Managing to Learn , by John Shook, The Lean Enterprise Institute, 2008.)

Seeing this first version, Sanderson uses the A3 process as a mechanism to mentor Porter in root-cause analysis and scientific thinking. Through coaching Porter and others in this manner, Sanderson seeks to embed organizational habits and mind-sets that enable, encourage and teach people to think and take initiative.

The iterative process of producing progressive A3s generates practical problem-solving skills for the learner, while providing the manager with a practical mechanism to mentor others while achieving desired business results.

The last pages of this article show the final A3 in this iterative sequence. Author Porter uses the A3 process not only to figure out the best solutions to his problem, but to manufacture the authority he needs to proceed with his plan. Sanderson uses it to mentor his protégé, while getting the required results for the company (in this instance, the solution to a problem). Organizations use A3s to get decisions made, distribute authority to the level needed for good decisions, align people and teams on common goals and learn for constant improvement. The ultimate goal of A3s is not just to solve the problem at hand, but to make the process of problem solving transparent and teachable in a manner that creates an organization full of thinking, learning problem solvers. In this way, the A3 management process powerfully embodies the essence of operational learning.

About the Author

John Shook is an industrial anthropologist and senior advisor to the Lean Enterprise Institute, where he works with companies and individuals to help them understand and implement lean production. He is author of Managing to Learn: Using the A3 Management Process to Solve Problems, Gain Agreement, Mentor, and Lead (Lean Enterprise Institute), and coauthor of Learning to See (Lean Enterprise Institute). He worked with Toyota for 10 years, helping it transfer its production, engineering and management systems from Japan to its overseas affiliates and suppliers.

More Like This

Add a comment cancel reply.

You must sign in to post a comment. First time here? Sign up for a free account : Comment on articles and get access to many more articles.

Comments (22)

Sheila colinlak, patrick doyle, acta de constitución de proyecto ágil, un elemento diferenciador. | agilia, dave whaley, william harrod, howard s weinberg, systemental, khucxuanthinh.

IMAGES

VIDEO